Back in November, MDL Technologies hosted its inaugural “Exploring EMC” event, bringing together some of the brightest minds in the EMC industry to showcase the latest technologies and innovations. Gathering at the British Motor Museum, the event played host to guest speakers from MDL’s range of technology partners to discuss EMC test standards, practical design for EMC compliance and how to prepare for a successful test programme.

Exploring EMC welcomed more than 80 attendees including guest speakers from Raditeq, Unit 3 Compliance, ETS-Lindgren and PMM Narda.

Key takeaways from the event

Radiated Emissions - Causes, Antennas, Noise, and Solutions

Kicking off the day was a talk and demonstration by James Pawson of Unit 3 Compliance. James carried out a live demonstration showing how radiated emissions occur from circuits using simple concepts and circuit theory.

Highlighting the differences in EMI Measurements performed by Spectrum Analyzers with EMC Functions vs. Pre and Full Compliant Receivers in the presence of Pulses with Low Repetition Frequency, according to the requirements of CISPR 16-1-1 Standard

Progressing into the morning, Dr. Eng. Michele Zingarelli, EMC Regional Manager from PMM Narda continued the seminar with his talk on the comparison of EMI measurement performance of a Spectrum Analyser, a Pre-Compliant Receiver, and a Full-Compliant Receiver. Also covered were upcoming changes in IEC/EN 55014-1 for Household Appliances, specifically the discontinuous interference test ‘clicks’ and the impact on the EMI Analysers that can be used.

Test methods for RF immunity testing

Patrick Dijkstra, of Raditeq explained the essential requirements for measuring equipment, with a particular focus on speed and accuracy. Patrick also discussed the performance and measurement criteria required by the EMC Immunity standards to cover all functions of the Device Under Test (DUT).

Considerations for a successful EMC Test program

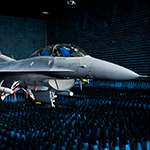

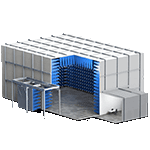

Closing the Seminar was Ryan Fergus, EMC Systems Engineer at ETS-Lindgren. The presentation provided helpful information on how to plan for a successful EMC test program, covering things like EMC test plans, pre-compliance testing, product configuration requirements, EUT performance monitoring, test standards and costs.

Exploring EMC Exhibition

In addition to our speakers, several of our technology partners such as Tektronix, Haefely, and Y.I.C Technologies had small stands at the event to showcase their latest offerings. Attendees had the opportunity to network with like-minded individuals and explore new horizons in this rapidly evolving field from trusted industry experts themselves.

“Thank you for everyone who made the effort to attend Exploring EMC from the UK and across Europe. This has been a successful event and is the first of many.”

– Mike Kennedy, Group Business Development Director

Want to get a more extensive recap of our

2023 Exploring EMC Seminars?

To watch the recordings of our seminar presentations from our guest speakers, please complete the short form below.